The Aghorn Hydrogen Sulfide accident

On October 26, 2019 there was a fatal injury due to a Hydrogen Sulfide accident at the Aghorn Operating Waterflood station in Odessa, Texas. The US Chemical Safety Board was investigating this accident and had released a report about the Hydrogen Sulfide incident, as was reported by us here.

The CSB has now released more details about this Hydrogen Sulfide accident which are available here.

Key findings about the H2S incident by the CSB

These are the important findings from the report. These are all contributory factors which may have led to the fatal Hydrogen Sulfide accident.

Non use of personal H2S Gas Detector.

The affected employee was not using a personal H2S gas detector (the gas detector was issued to him but he had left in the truck parked outside. Significantly, the detector had set off and was in an alarm state). If he has used the detector then probably he could have been warned about it and saved himself.

Non use of LOTO- Lock Out Tagout procedures by the management.

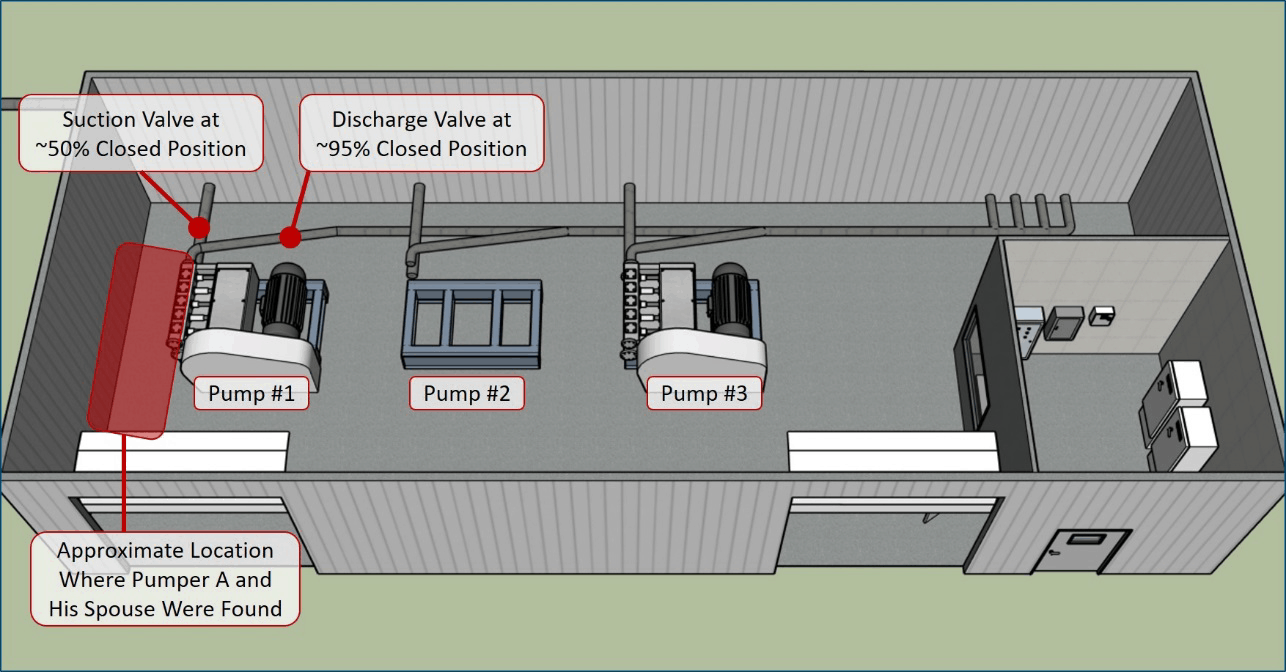

There were supposed to be verbal LOTO procedures but there was no written procedure. The pump that the affected employee was working on suddenly started while he was working on it and the discharge contained water that had H2S inside. The pump was operated via a PLC and started suddenly based on the PLC program. It was not manually taken offline as it would have had a proper LOTO Procedure existed.

Non working H2S gas detection system

The fixed toxic gas detectors meant for H2S detection as well as the entire gas detection system installed at the site were not functional and had not been maintained for many years apparently. Hence high levels of H2S did not trigger any general alarm at the facility.

Poor perimeter security

There was a fence but the gate was not locked. The employee’s spouse went inside to look for him and was also unfortunately killed due to the H2S gas inside.

Poor Ventilation

The pump house had three pumps inside which used to operate intermittently throughout the day. The pumped water contained H2S gas but there was no ventilation system to vent it out of the confined space. The pump house doors were left open but this was insufficient to remove the H2S inside the room.

Was this a Preventable H2S Accident?

Could the accident have been prevented? Sure. The accident was completely preventable had proper training. This training is now available online for free such as this free Hydrogen Sulfide training course and this free LOTO Training course.

The above incident once again shows us that proper working H2S gas detectors, employee awareness about the dangers of Hydrogen Sulfide, using a proper LOTO procedure can save lives.